| Terminal thickness: 6.2 | ||||

| Rigid conductor | Flexible conductor | I | Ui | |

| (mm2) | (A) | (V) | ||

| IEC 60947-7-1 | 0.2-4 | 0.2-4 | 32* | 500 |

| * The total current of all the connected conductors should not exceed the maximum rated working current of the terminal. | ||||

Products Category

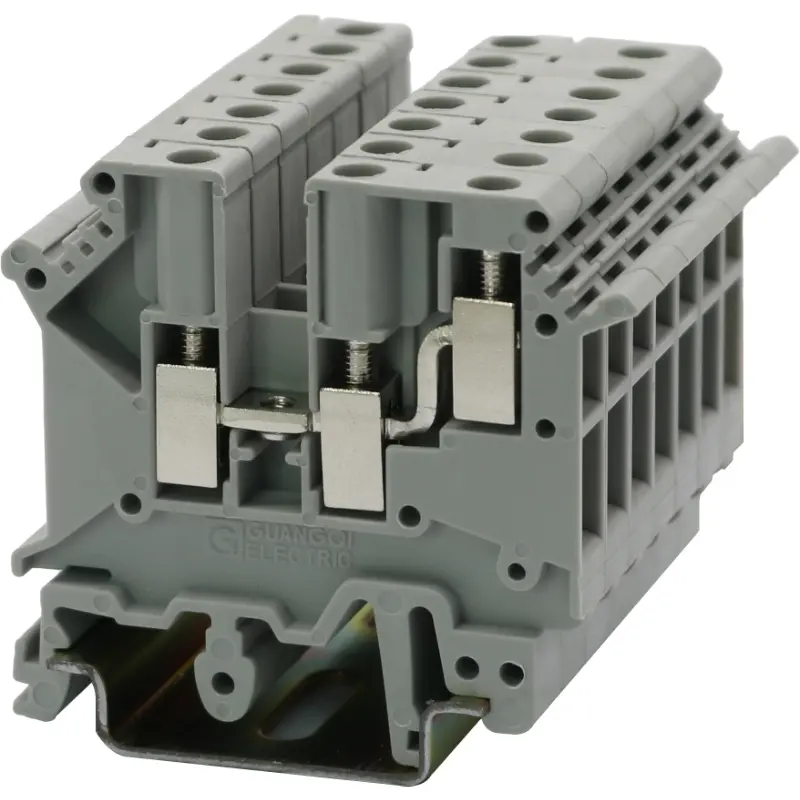

JWD1-4/1-2 Screw Type Din-Rail TB

Product Description

Parameters

Certification

| Description | Color | Type |

| Terminal: With general-purpose locating base, suitable for standard mounting rails |

Grey | JWD14/1-2 |

| Blue | JWD14/1-2 BU | |

| Ground terminal: The yellow-green insulating housings are suitable for the standard mounting rails |

||

| (1) End plate: One additional piece must be attached to the end of each terminal strip set. If it is mounted in the center of the terminal strip, the creepage distance may increase. |

Grey | 4/1-2 G |

| Blue | 4/1-2 G BU | |

| (2) Central liaison part: It is used to connect terminals with the same specification and form a liaison terminal group; each part has 10 digits (supplied with screws) that can be further divided at will. |

ZL 6/10 | |

| (3) Connecting sheet: For central connection of more than 10 digits |

LJ 6/2 | |

| (4) Edge liaison part: Its role is the same as that of the central liaison part (2); with insulation on the back side; 10 digits that can be further divided at will |

2 digits: | BL 6/2 |

| 3 digits: | BL 6/3 | |

| 10 digits: | BL 6/10 | |

| (5) Jumping liaison part: With the spacer (6), it can connect any non-adjacent terminals in the center to form a jumping liaison terminal group. |

KL 6/10 | |

| (6) Spacer: Used as a spacer block between the accessory of the jumping liaison part (5) and the conductive part of the terminal |

K 6 | |

| (7) Switch liaison part: To be used on top of the terminal for switch connection; the end plate (1) should be added between the connected terminals to ensure electrical isolation. |

HL 6/2 | |

| (8) Divider: It is used to separate two adjacent liaison terminal groups and can be inserted after assembly, without any effect on the overall space. |

GP | |

| (9) Tag: It can be quickly inserted in the upper grooves on both sides of the terminal as a whole for any identification. It has a total of 10 digits (to be divided at will). |

ZP6 |

| Terminal dimensions | ||

| Thickness / width / end plate thickness | [mm] | 6.2/50.5/2 |

| Height (TH 35:7.5 / TH 35:15 / G 32:15) | [mm] | 47/54.5/52 |

| Technical data based on IEC/DIN VDE standards | ||

| Maximum rated working current / cross-sectional area | [A] / [mm2] | 11780 |

| Maximum cross-sectional area of conductors (rigid / flexible) that can be connected if any edge liaison part is used: | [mm2] | 45386 |

| Rated impulse withstand voltage / degree of pollution | [kV]/- | 45446 |

| Over-voltage category / insulation material group | -/- | lll/l |

| Feed-through layer: connecting two conductors with the same cross-sectional area | ||

| Flexible conductor with tubular bare terminal / tubular pre-insulated terminal | [mm2] | 0.25-4/0.25-2.5 |

| Connection of multiple conductors (two conductors with the same cross-sectional area) | ||

| Rigid conductor / flexible conductor | [mm2] | 0.2-1.5/0.2-1.5 |

| Flexible conductor with tubular bare terminal | [mm2] | 0.25-1.5 |

| Flexible conductor with DEV-tubular pre-insulated terminal | [mm2] | 0.5-1.5 |

| Stripping length | [mm] | 8 |

| Screw for terminal position: screw type / torque | M 3/0.6-0.8 | |

| Central fastening screw: screw type / torque | [Nm] | |

| Insulation material type | PA | |

| Material flammability according to UL94 | V0 | |

| Rated working voltage / rated working current / wire gauge | UL:[V]/[A]/AWG | 150/30/30-10 |

| Note: When an edge liaison part is used, a cable below 1.5 mm2 should be used for a 2.5 mm2 terminal; corresponding cables should be used for terminals with other cross-sectional areas (mm2). |

Welcome to consult us for more information!