| Terminal thickness: 5.2 | ||||

| Rigid conductor | Flexible conductor | I | Ui | |

| (mm2) | (A) | (V) | ||

| IEC 60947-7-1 | 0.2-4 | 0.2-2.5 | 24 | 500 |

Products Category

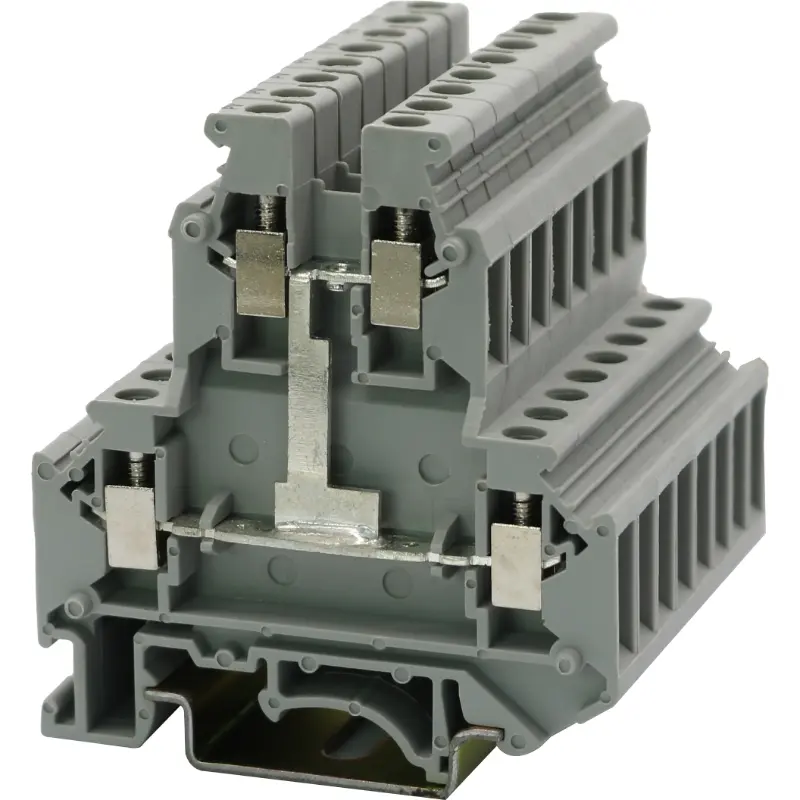

JWD1-2.5/2L Screw Type double layer Din-Rail TB

- The double-layer terminal has the double connection capacity in the same spatial position compared to the basic-type terminal. This plays a crucial role in the applications where the connection space is limited.

- In terms of design, there is a 2.5 mm space between the upper and lower layers of the double-layer terminal. This provides a well-arranged hierarchical structure. Besides, in case of full connection in the upper layer, this can also facilitate connection with screwdriver in the lower layer of the terminal, with clear identification; after a compensating end plate is mounted, the terminal locating and fastening of the terminal strip or the assembly of other types of terminals will not be affected, and orderly arrangement can be ensured.

- The double-layer interconnected terminal can connect multiple conductors to one terminal in order to achieve "potential distribution" or due to a loop branch. This avoids the need for adjacent arrangement of multiple terminal groups and for electric connection via a central liaison part because both solutions will increase the installation space and costs.

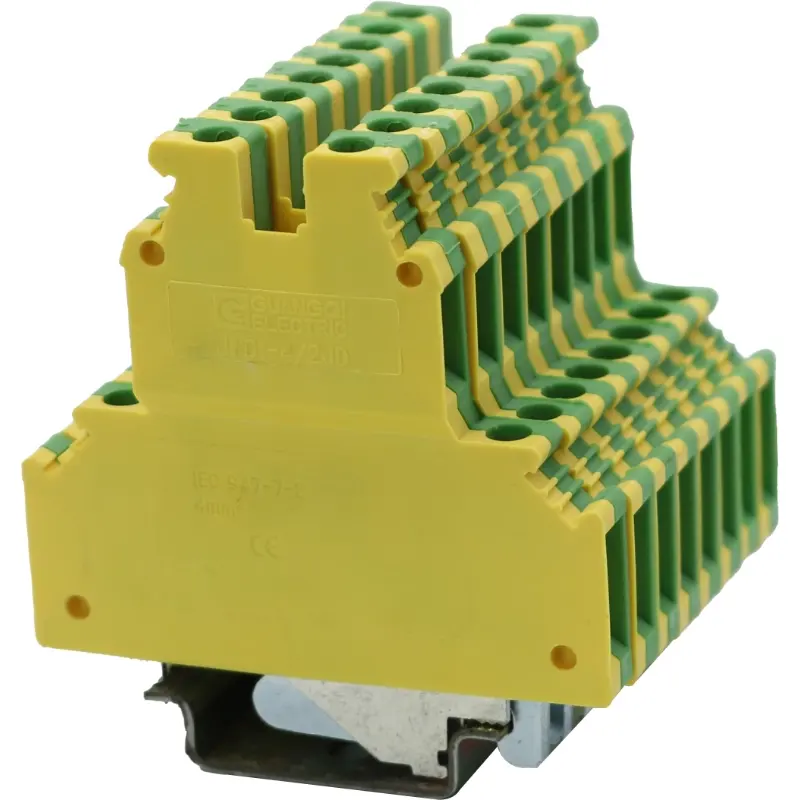

The yellow-green closed-end insulating housings of the double-layer ground terminal has the same configuration as the double-layer terminal, so their compatible adjacent arrangement is possible.

Product Description

Parameters

Certification

| Description | Color | Schematic diagram | Type | |

| Terminal: | Grey | JWD1-2.5/2 L | ||

| With general-purpose locating base, suitable for standard mounting rails | ||||

| and | ||||

| Blue | JWD1-2.5/2L BU | |||

| Top and bottom interconnected terminals: | Grey | |||

| The mounting and use methods are the same as above; the conducting plates in the upper and lower layers are interconnected to achieve the same potential of top and bottom connecting points. | ||||

| Blue | ||||

| (1) End plate: (thickness: 2.5) | Grey | 2.5-4/2 LG | ||

| One additional piece must be attached to the end of each terminal strip set. If it is mounted in the center of the terminal strip, the creepage distance may increase. | ||||

| Blue | 2.5-4/2 LG BU | |||

| (2) Compensating end plate: (thickness: 2.5) | Grey | 2.5-4/2LBD | ||

| It is used to offset interlayer displacement while it is adjacent to an ordinary terminal. | ||||

| Blue | 2.5-4/2LBD BU | |||

| (3) Compensating end plate: (thickness: 2.5) | 2.5-4/2L BD-1 | |||

| It is used for terminal locating and fastening of the terminal strip or for offsetting interlayer displacement while it is arranged with other terminals in the same group. | ||||

| (4) Central liaison part: | ZLB5/10 | |||

| It is used to connect terminals with the same specification and form a liaison terminal group; each part has 10 digits (supplied with screws) that can be further divided at will. | ||||

| (5) Connecting sheet: | LJ 5/2 | |||

| For central connection of more than 10 digits | ||||

| (6) Edge liaison part: | 2 digits: | BL5/2 | ||

| Its role is the same as that of the central liaison part (4); with insulation on the back side; 10 digits that can be further divided at will | ||||

| 3 digits: | BL5/3 | |||

| 10 digits: | BL5/10 | |||

| (7) Jumping liaison part: | KL5/10 | |||

| With the spacer (8), it can connect any non-adjacent terminals in the center to form a jumping liaison terminal group. | ||||

| (8) Spacer: | KB5 | |||

| Used as a spacer block between the accessory of the jumping liaison part (7) and the conductive part of the terminal | ||||

| (9) Divider: | GP-1 | |||

| It is used to separate two adjacent liaison terminal groups and can be inserted after assembly, without any effect on the overall space. | ||||

| (10) Group partition: (thickness: 2.5) | 2.5-4/2 LG F | |||

| Used for separation of each terminal group; with dual effects (visible grouping and electrical isolation) | ||||

| (11) Tag: | ZP5 | |||

| Terminal dimensions | ||

| Thickness / width / end plate thickness | [mm] | 5.2/67/2.5 |

| Height (TH 35:7.5 / TH 35:15 / G 32:15) | [mm] | 62 / 69.5 / 67 |

| Technical data based on IEC/DIN VDE standards | ||

| Maximum rated working current / cross-sectional area | [A] / [mm2] | Apr-32 |

| Maximum cross-sectional area of conductors (rigid / flexible) that can be connected if any edge liaison part is used: | [mm2] | 2.5/2.5 |

| Rated impulse withstand voltage / degree of pollution | [kV]/- | 6月3日 |

| Over-voltage category / insulation material group | -/- | lll/l |

| Connection capacity | ||

| Flexible conductor with tubular bare terminal / tubular pre-insulated terminal | [mm2] | 0.25-2.5/0.25-1.5 |

| Connection of multiple conductors (two conductors with the same cross-sectional area) | ||

| Rigid conductor / flexible conductor | [mm2] | 0.2-1/0.2-1.5 |

| Flexible conductor with tubular bare terminal | [mm2] | 0.25-1.5 |

| Flexible conductor with DEV-tubular pre-insulated terminal | [mm2] | 0.5-1 |

| Stripping length | [mm] | 8 |

| Screw type | M3 | |

| Torque | [Nm] | 0.6-0.8 |

| Insulation material type | PA | |

| Material flammability according to UL94 | V0 | |

| Rated working voltage / rated working current / wire gauge | UL:[V]/[A]/AWG | 600/20/28-12 |

| Note: When an edge liaison part is used, a cable below 1.5 mm2 should be used for a 2.5 mm2 terminal; corresponding cables should be used for terminals with other cross-sectional areas (mm2). | ||

Welcome to consult us for more information!